In the ever-evolving automotive industry, optimizing engine performance and extending longevity have become paramount objectives, leading to the increased adoption of technologies such as the Air Cooled Oil Cooler. According to a report by the Society of Automotive Engineers, effective cooling systems can enhance engine efficiency by up to 10%, significantly impacting fuel consumption and emissions. Air Cooled Oil Coolers play a critical role in managing engine temperatures by dissipating heat from the oil, ensuring that the engine operates within its optimal temperature range. This not only improves lubricating properties but also minimizes the risk of overheating-related failures. As engines produce more power and run hotter, the importance of superior cooling solutions like the Air Cooled Oil Cooler becomes increasingly clear, highlighting its potential to prolong engine life and reduce maintenance costs. Understanding these benefits is essential for those looking to maximize their engine's reliability and efficiency.

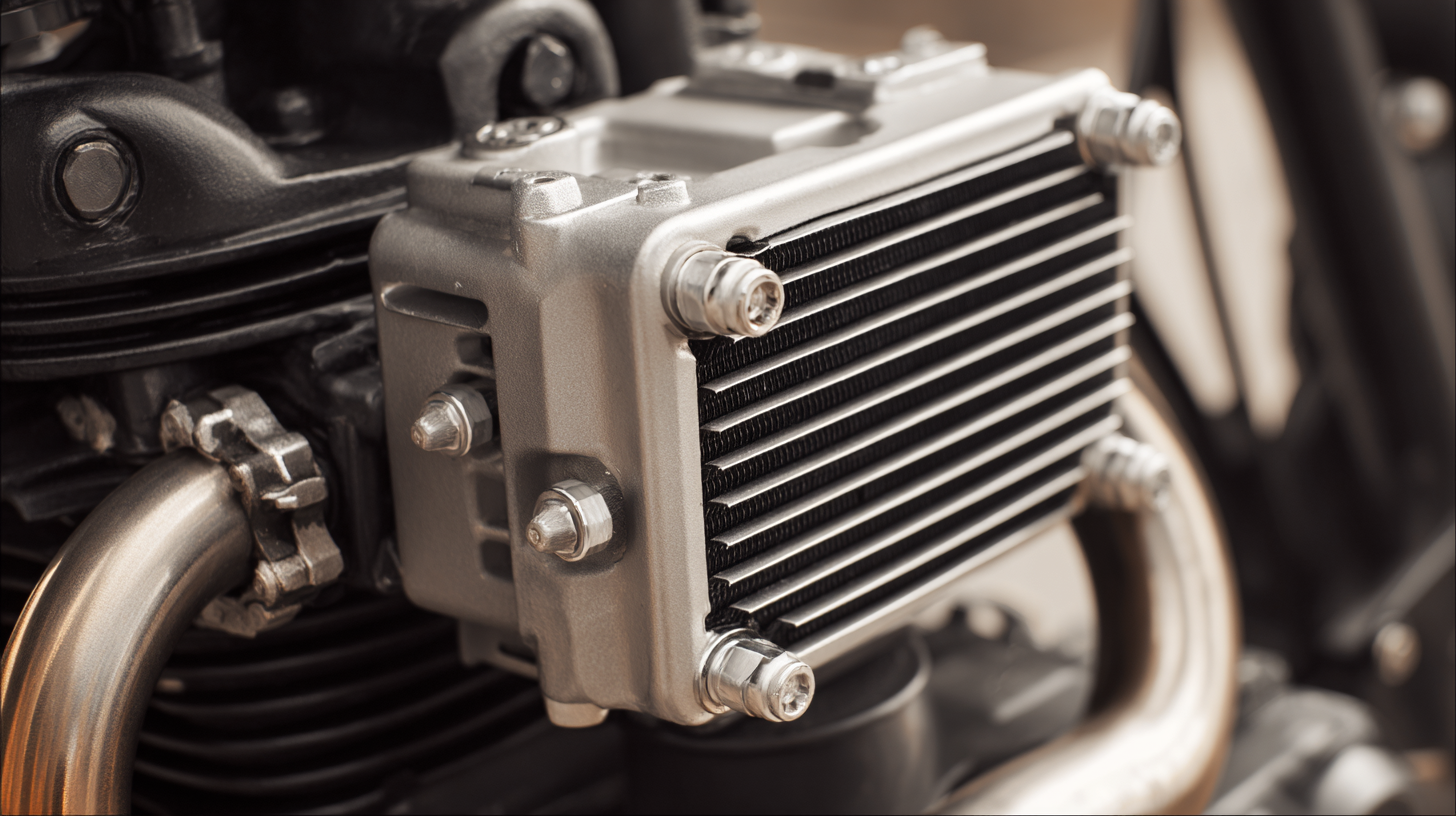

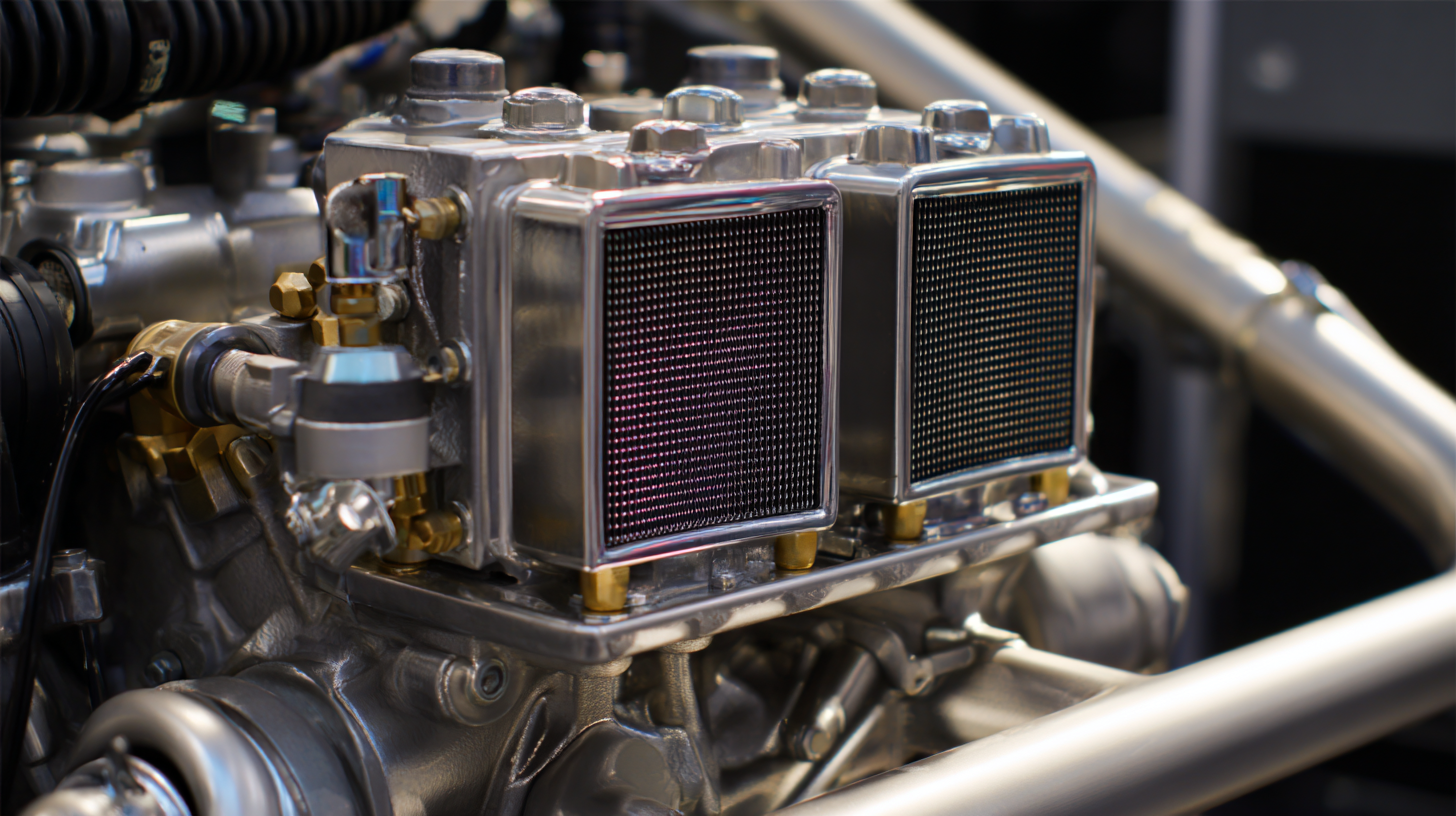

Air cooled oil coolers play a crucial role in maintaining optimal engine temperatures, which is vital for engine performance and longevity. These coolers operate on the principle of heat exchange, where the hot oil circulating through the engine is routed through a series of fins or tubes in the cooler. As the hot oil passes through, ambient air flows over the surfaces, absorbing excess heat from the oil. This process effectively lowers the oil temperature before it returns to the engine, ensuring that the oil maintains its viscosity and lubricating properties.

The efficiency of air cooled oil coolers hinges on their design and the flow of air around them. Engineers often optimize the surface area of the cooler to maximize heat transfer and ensure efficient cooling under various operating conditions. Additionally, the placement of the cooler is crucial; it needs to be positioned where airflow is maximized, such as near the front of the vehicle or in areas with minimal obstruction. By managing engine temperatures effectively, air cooled oil coolers contribute significantly to improved engine efficiency and a longer operational lifespan, reducing the risk of overheating and potential engine failures.

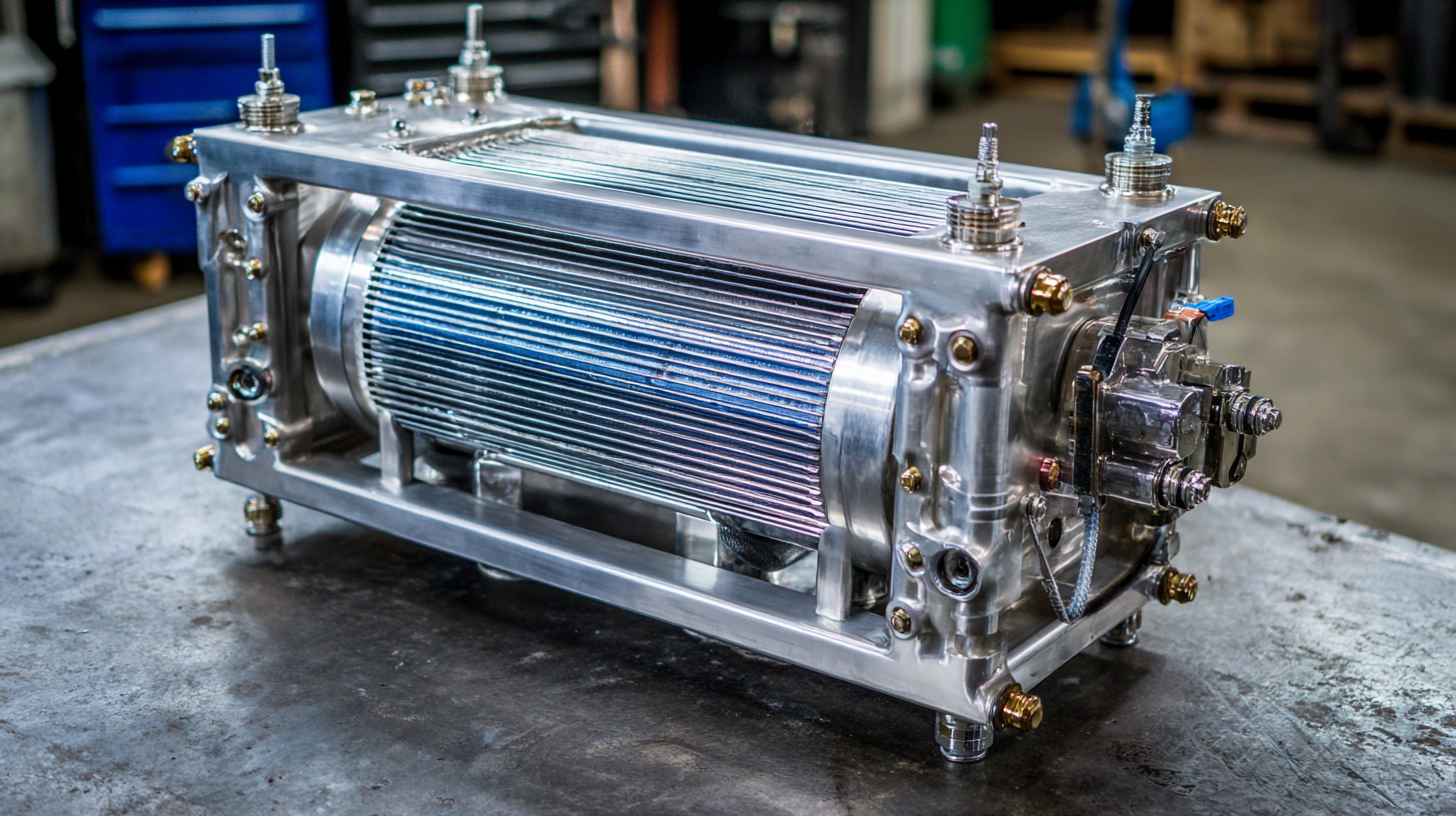

Air cooled oil coolers play a crucial role in enhancing engine performance and durability by efficiently managing oil temperatures. Unlike traditional liquid-cooled systems, air cooled oil coolers utilize air flow to dissipate heat from the engine oil, which can significantly improve the overall efficiency of the engine. By maintaining optimal oil temperatures, these coolers help reduce friction between moving parts, ensuring that the engine runs smoother and consumes less fuel. This efficiency not only translates into better performance but also contributes to a more environmentally friendly operation by reducing emissions.

Moreover, the durability of an engine is markedly improved with the use of air cooled oil coolers. Overheating can lead to accelerated wear and tear on engine components, decreasing its lifespan. By keeping the oil at a stable temperature, air cooled oil coolers help prevent thermal breakdown and oxidation of the oil, promoting long-term protection for vital engine parts. This added level of protection is essential for maintaining the reliability of engines over time, especially in demanding applications like racing or heavy-duty use, where consistent performance is crucial.

Air cooled oil coolers play a crucial role in enhancing engine efficiency and longevity, particularly in high-performance automotive and industrial applications. According to industry reports, the implementation of air cooled oil coolers can lead to significant reductions in operating temperatures, which is pivotal for maintaining optimal engine performance. Data from recent studies indicate that engines equipped with these coolers can experience efficiency improvements of up to 10% due to better heat management. Moreover, by keeping the oil at a steady temperature, these coolers extend the lifespan of both the oil and the engine components, minimizing wear and tear over time.

Tips for optimizing the use of air cooled oil coolers include regular maintenance to ensure air flow is unobstructed and checking for any signs of wear in the cooler itself. Additionally, pairing these coolers with high-quality oil designed for performance applications can further amplify the benefits. As the need for improved thermal management solutions grows, the broader cooling market is expected to expand significantly. Industry forecasts show that the data center liquid immersion cooling market will witness a CAGR of over 25.6% from 2025 to 2032, highlighting the increasing recognition of effective cooling technologies across various sectors. Embracing air cooled oil coolers now can position operators ahead of the curve in engine efficiency and longevity.

| Parameter | Value | Percentage Improvement |

|---|---|---|

| Oil Temperature Reduction (°C) | 15 | 20% |

| Engine Life Extension (hours) | 5000 | 25% |

| Fuel Efficiency Improvement (MPG) | 2.5 | 10% |

| Maintenance Interval Extension (miles) | 3000 | 15% |

| Cooling Efficiency Improvement (%) | 30 | 30% |

When considering the integration of air cooled oil coolers with various engine types, it's essential to understand the unique compatibility requirements that arise. Different engines have specific cooling needs based on their design, horsepower targets, and operational conditions. Therefore, selecting an air cooled oil cooler that aligns with the engine's specifications ensures optimal performance and longevity. Proper installation is crucial; it involves assessing the mounting points, airflow dynamics, and connections to ensure the cooler operates efficiently without obstructing other vital components.

Compatibility also extends to the coolant used alongside air cooled oil coolers. With the rise of aluminum engines, careful consideration must be taken regarding coolant types. Certain coolants, especially those containing nitrites, can react adversely with aluminum parts, potentially leading to engine damage over time. As a result, selecting the right coolant and additives becomes a key factor in maintaining the health of both the engine and the cooling system. Through meticulous planning and adherence to compatibility standards, integrating air cooled oil coolers can significantly enhance engine efficiency and prolong its lifespan.

Air cooled oil coolers play a vital role in enhancing engine efficiency and prolonging its lifespan by maintaining optimal oil temperatures. However, to ensure these components function effectively, regular maintenance is essential. Here are some crucial tips to keep your air cooled oil coolers in top shape.

Firstly, routinely inspect the cooler for any signs of debris accumulation or damage. Dust, dirt, and other particles can obstruct airflow, reducing cooling efficiency. Cleaning the cooler with compressed air or a soft brush can help maintain air passage and improve performance. Additionally, pay attention to any leaks or corrosion, as these issues may lead to catastrophic failures if not addressed promptly.

Secondly, check the oil levels and quality periodically. Using high-quality oil that meets your engine’s specifications not only optimizes performance but also aids in the cooler's function. If you notice any unusual changes in oil viscosity or color, consider changing the oil to prevent overheating. Lastly, schedule regular professional evaluations to monitor the cooler's performance and address potential problems before they escalate. By following these maintenance tips, you can ensure your air cooled oil cooler operates efficiently, resulting in an engine that runs smoothly for years to come.