In the realm of industrial hydraulics, the efficiency and longevity of equipment heavily rely on the performance of the Hydraulic Oil Cooling System. A well-optimized cooling system is crucial, as elevated oil temperatures can lead to reduced lubrication properties, increased wear on components, and ultimately, system failures. According to a report by the International Journal of Advanced Manufacturing Technology, nearly 30% of hydraulic system failures can be attributed to overheating, which underscores the necessity of robust cooling solutions. Furthermore, maintaining hydraulic oil at optimal temperatures can enhance system efficiency by as much as 10%, as highlighted in a study from the Hydraulic Oil Research Institute. This guide aims to provide comprehensive strategies for optimizing your Hydraulic Oil Cooling System, ensuring peak performance and reliability in your operations.

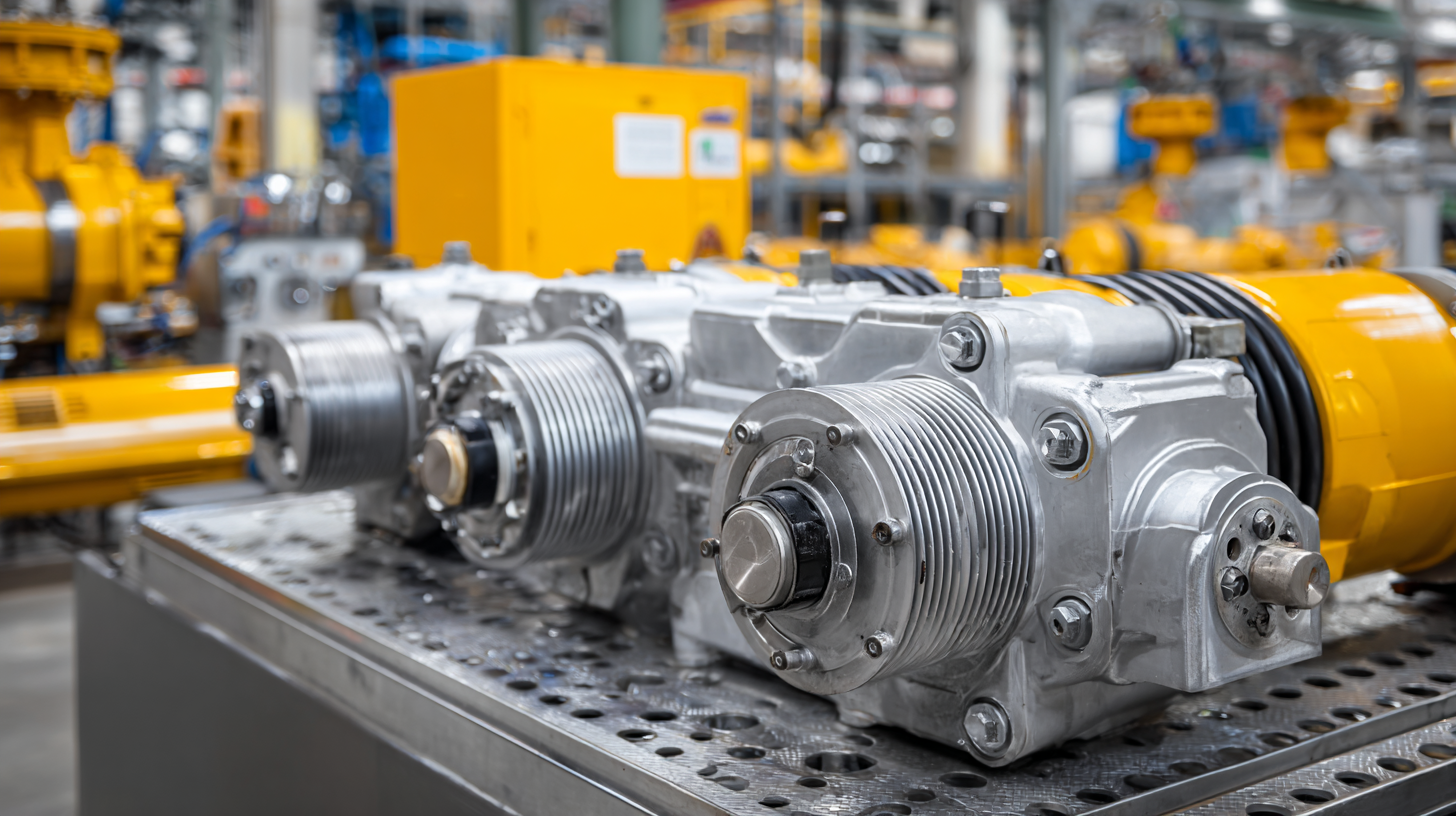

When selecting the right hydraulic oil cooler, several essential factors must be taken into consideration to optimize performance and ensure system longevity. Firstly, the cooler's capacity is paramount; it should match the system's hydraulic flow requirements. According to a 2021 report by the International Fluid Power Society, systems that operate with an inadequate cooler capacity can overheat, leading to a reduction in oil viscosity and accelerated wear on hydraulic components.

The design of the cooler is another critical aspect. Plate, shell-and-tube, and air-cooled designs offer varying efficiency levels and maintenance requirements. As per the National Fluid Power Association, choosing a plate cooler for applications with limited space can enhance heat dissipation by up to 25% more than traditional designs. Additionally, factors such as ambient temperature and operating environment should influence the type of cooler selected, ensuring optimal performance under diverse conditions.

Lastly, material compatibility should not be overlooked. Coolers made from corrosion-resistant materials can significantly extend the lifespan of the system. A study conducted by the Hydraulic Institute found that using the wrong materials could decrease cooler efficiency by 30%. Therefore, paying attention to these vital elements can lead to improved overall performance and reduced operational costs in hydraulic systems.

When it comes to optimizing your hydraulic oil cooling system, avoiding common design mistakes is crucial for ensuring peak performance. One prevalent error is neglecting to account for air entrainment, which can lead to reduced cooling efficiency. Air bubbles can form in the hydraulic fluid, diminishing heat transfer and potentially damaging system components. Implementing measures to minimize air infiltration, such as proper tank design and venting, can significantly enhance system reliability.

Another frequent mistake is improper sizing of cooling components. An oversized cooler may lead to sluggish performance, while an undersized unit can overheat, compromising the entire hydraulic system. It’s essential to conduct thorough calculations based on the specific operational requirements, including flow rates and expected heat loads, to determine the optimal size and type of cooler. Additionally, overlooking the importance of regular maintenance can result in the accumulation of dirt and debris, which obstructs the cooling process. Establishing a routine inspection schedule can help maintain system efficiency and longevity.

Maintaining optimal cooling efficiency in hydraulic oil cooling systems is crucial for ensuring peak performance. Regular maintenance not only extends the life of the components but also improves the system's overall effectiveness. According to a report by the International Fluid Power Society, effective maintenance can enhance machine reliability by up to 30%, thereby reducing costs associated with unscheduled downtime.

Tip 1: Regularly inspect and clean the cooling system filters. Dirty filters can restrict flow and lead to overheating, which could result in significant system failures. It is recommended to check filters at least every 500 operating hours to ensure they are free from debris and contaminants.

Tip 2: Monitor oil temperature and viscosity consistently. The ideal operating temperature for most hydraulic oils ranges between 50°C to 70°C. Utilizing temperature monitoring devices and adhering to the manufacturer's viscosity specifications can help maintain hydraulic fluid within optimal parameters. According to a study by the American Society of Mechanical Engineers, maintaining appropriate viscosity can improve energy efficiency by up to 15%.

Tip 3: Ensure proper airflow around the cooling unit. Blocked or insufficient airflow can drastically reduce cooling efficiency, leading to potential overheating. Positioning cooling units in open areas and regularly cleaning external surfaces from dust and debris can significantly enhance performance.

| Maintenance Tip | Frequency | Expected Outcome | Remarks |

|---|---|---|---|

| Regular Oil Analysis | Quarterly | Detect contaminants early | Utilize laboratory testing |

| Heat Exchanger Inspection | Biannually | Prevent overheating | Clean as necessary |

| Check Cooling Fluid Levels | Monthly | Ensure efficient cooling | Top off if low |

| Replace Filters | Annually | Improve fluid cleanliness | Use OEM filters |

| Monitor Temperature | Continuously | Ensure optimal operation | Install reliable sensors |

| Inspect Hoses and Fittings | Monthly | Prevent leaks | Look for wear or damage |

| System Flush | Every 3 years | Remove sludge and deposits | Follow manufacturer's guidelines |

To ensure peak performance of your hydraulic oil cooling system, monitoring key metrics is crucial. The first essential metric is oil temperature. Maintaining the hydraulic oil within the optimal temperature range not only enhances system efficiency but also prolongs equipment life. Elevated temperatures can lead to oil degradation, which impairs lubrication and can increase wear and tear on system components. Regularly checking oil temperature can help identify any cooling system deficiencies early, enabling prompt maintenance actions.

The second critical metric is flow rate. An adequate flow rate ensures that the hydraulic oil circulates efficiently, allowing for effective heat transfer. Monitoring this metric can help detect potential blockages or pump malfunctions that could impede the cooling process. Finally, pressure differentials across the cooling system indicate the system's efficiency in dissipating heat. A significant drop in pressure can suggest fouling in heat exchangers or other operational issues. By diligently tracking these three key metrics—oil temperature, flow rate, and pressure differentials—you can optimize your hydraulic oil cooling system, ensuring it operates at its best and supports overall machinery performance.

This chart illustrates three key metrics that are crucial for monitoring the performance of your hydraulic oil cooling system: Oil Temperature, System Pressure, and Flow Rate. Keeping these metrics in optimal ranges ensures peak performance and longevity of the system.

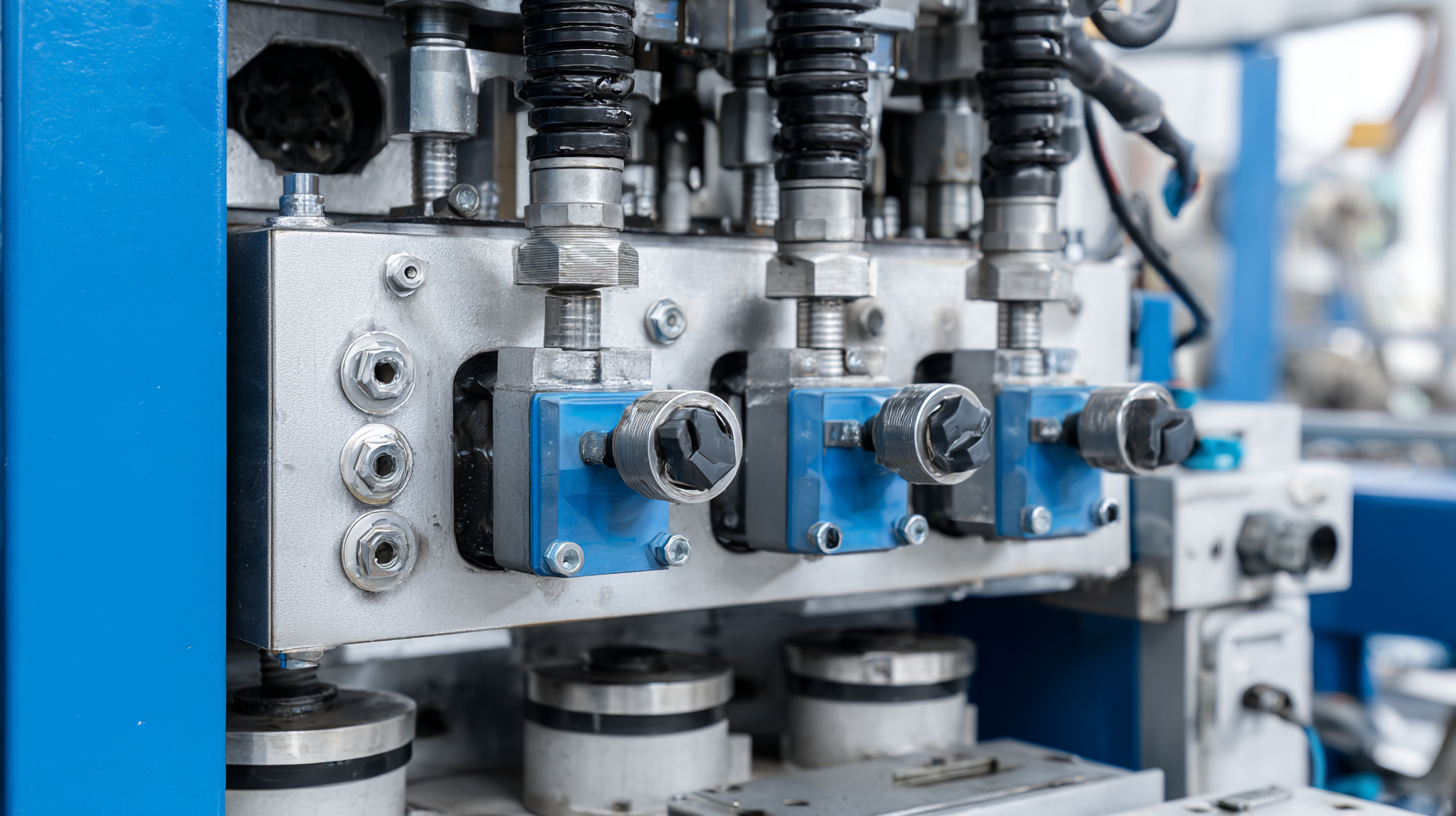

When it comes to enhancing the performance of hydraulic oil cooling systems, integrating advanced technologies can make a significant difference. One of the foremost innovations is the use of high-efficiency heat exchangers that maximize heat transfer while minimizing pressure drop. These exchangers can adapt to varying flow rates, ensuring optimal cooling under different operating conditions. Additionally, employing variable speed pumps allows for tailored cooling based on real-time system demands, improving energy efficiency and prolonging equipment lifespan.

Another cutting-edge approach involves the use of smart monitoring systems equipped with IoT sensors. These sensors provide continuous data on temperature, viscosity, and oil condition, enabling proactive maintenance and prompt responses to potential issues. Furthermore, incorporating advanced filtration technologies enhances oil quality by removing particulates and contaminants, thereby reducing wear on hydraulic components. By harnessing these technologies, operators can significantly boost the effectiveness of their hydraulic cooling systems, leading to improved operational reliability and reduced downtime.