In the ever-evolving landscape of technology and engineering, understanding the mechanics behind cooling systems is crucial for enhancing performance and efficiency in various applications. Cooling systems play a vital role in regulating temperature across multiple industries, from automotive to data centers, ensuring operational reliability and longevity of equipment.

This blog explores the types and functionalities of cooling systems, shedding light on their design principles and the specific challenges they address. By delving into the underlying mechanisms of these systems, we aim to provide a comprehensive understanding of their importance and applications in modern technology, ultimately informing readers about the innovative solutions available for temperature management.

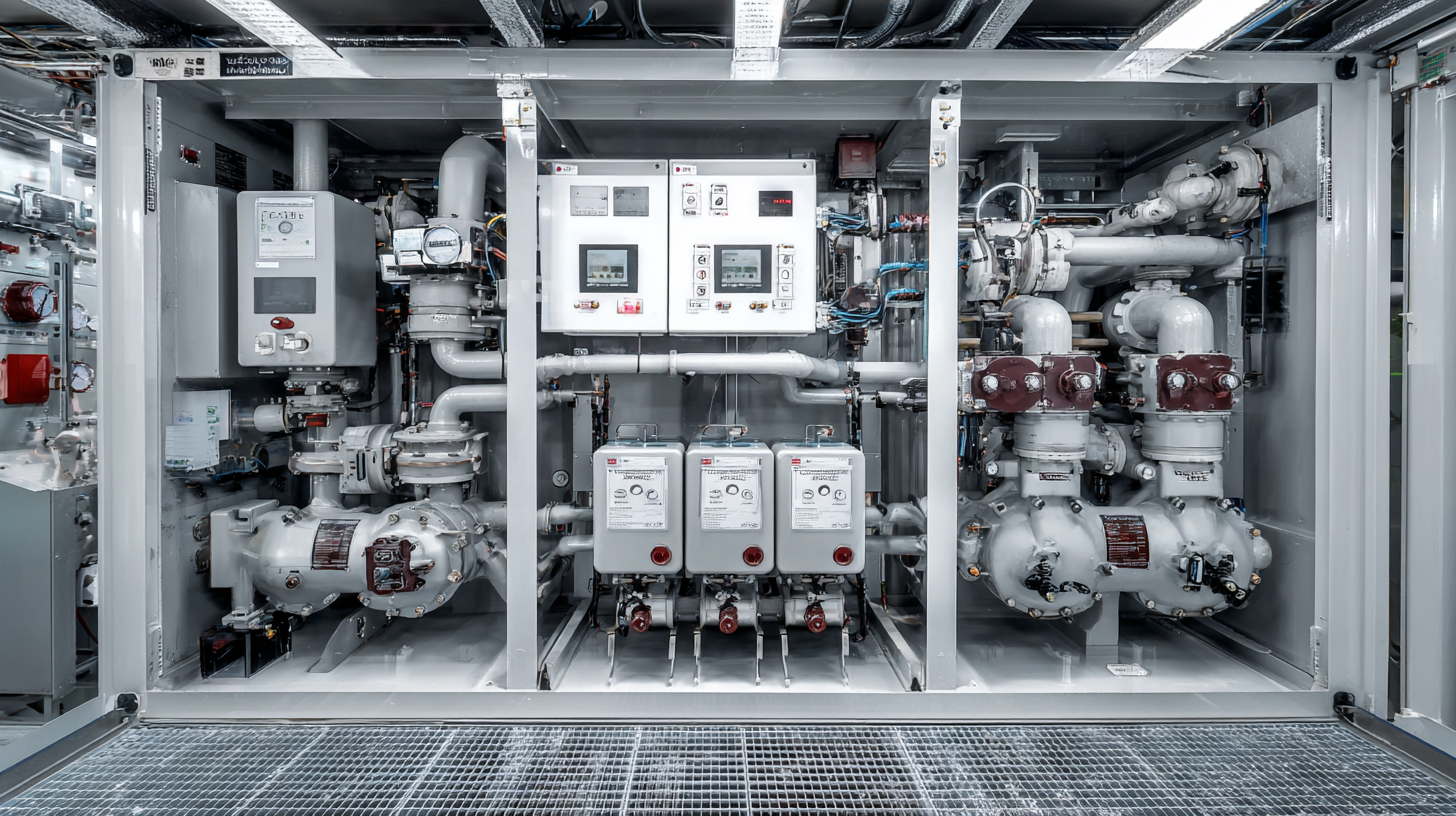

Cooling systems play a crucial role in various industrial and residential applications, ensuring optimal temperature control and enhancing operational efficiency. At the core of these systems are key components such as condensers, evaporators, and compressors. According to the International Energy Agency (IEA), industrial cooling accounts for approximately 20% of global energy consumption, highlighting the importance of these components in energy efficiency and sustainability initiatives.

Condensers serve to dissipate heat absorbed by refrigerants and are critical for maintaining system stability. The type of condenser, whether air-cooled or water-cooled, can significantly affect performance and energy usage. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) notes that optimizing condenser design can reduce energy consumption by up to 30%. Similarly, evaporators are designed to facilitate the heat absorption process and can significantly impact the overall efficiency of the cooling system. When properly maintained, these components can improve system longevity and efficiency, providing substantial savings over time.

Compressors are vital for circulating refrigerant throughout the system, transitioning it between different states to facilitate heat exchange. The U.S. Department of Energy provides data that indicates using high-efficiency compressors can lower energy costs by 15-25% compared to standard models. As industries strive for greater energy efficiency and reduced operating costs, understanding these key components becomes essential for effective cooling system design and application.

Cooling systems play a pivotal role in a variety of industries, facilitating the efficient management of heat to preserve equipment functionality and enhance performance. The science of heat transfer is central to these systems, which rely on mechanisms such as conduction, convection, and radiation.

Conduction, the direct transfer of thermal energy through materials, is crucial in applications where solid components must manage heat without fluid movement. Meanwhile, convection, involving the movement of fluids, allows for more dynamic heat dissipation, making it essential in environments like data centers or automotive systems where temperature management is critical.

Cooling systems play a pivotal role in a variety of industries, facilitating the efficient management of heat to preserve equipment functionality and enhance performance. The science of heat transfer is central to these systems, which rely on mechanisms such as conduction, convection, and radiation.

Conduction, the direct transfer of thermal energy through materials, is crucial in applications where solid components must manage heat without fluid movement. Meanwhile, convection, involving the movement of fluids, allows for more dynamic heat dissipation, making it essential in environments like data centers or automotive systems where temperature management is critical.

In addition to these mechanisms, the concept of thermal radiation is significant in cooling solutions. It is the emission of energy as electromagnetic waves, which can be exploited in designing radiative cooling systems that leverage the natural heat transfer to the environment. Understanding these principles enables engineers to optimize cooling systems for specific applications, ensuring that they maintain efficiency even under varying operational conditions. By applying these scientific concepts, industries can mitigate overheating risks, improve reliability, and extend the lifespan of their equipment, demonstrating the profound impact of cooling system design on operational success.

When it comes to cooling systems, understanding the different types available is crucial for selecting the right solution for your specific needs. Broadly, cooling systems can be categorized into three main types: air cooling, liquid cooling, and phase change cooling.

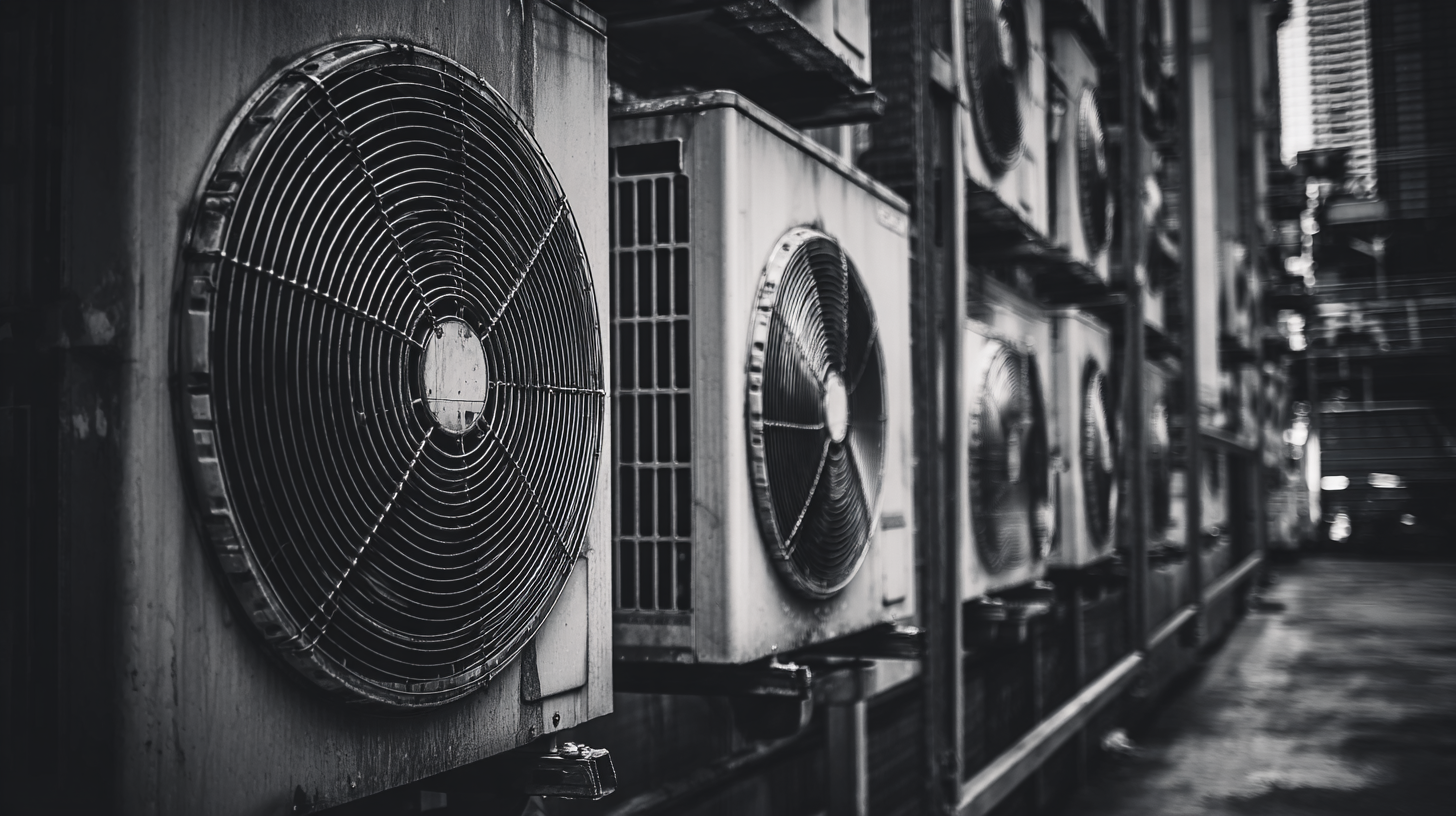

Air cooling systems are typically more common and are often used in residential and small commercial applications. They work by circulating air across heat exchangers to facilitate heat transfer. This method is typically easier to install and maintain, making it suitable for smaller spaces. On the other hand, liquid cooling systems utilize a liquid coolant to absorb and dissipate heat, making them more efficient for larger operations or high-performance environments. They require more intricate installations and maintenance but can offer significant performance advantages in terms of heat management.

Lastly, phase change cooling systems leverage the principles of thermodynamics, utilizing materials that change states (from solid to liquid to gas) to absorb substantial amounts of heat. This technology is particularly useful in specialized applications like data centers and some industrial processes where temperature control is critical. Understanding these cooling system types will help you choose the most efficient and cost-effective solution tailored to your specific operational requirements.

Cooling systems play a crucial role across a variety of industries, ensuring optimal operational conditions and enhancing the efficiency of processes. In the manufacturing sector, for instance, cooling systems are essential in metalworking. They maintain machinery temperatures, preventing overheating and wear, which can lead to costly downtimes. Furthermore, in the food and beverage industry, cooling systems preserve the quality and safety of products by regulating temperatures during processing and storage, thus extending shelf life and preventing spoilage.

In the tech industry, efficient cooling mechanisms are vital for data centers. They regulate the temperature of servers and other IT equipment, maintaining performance and preventing data loss due to overheating. Additionally, the automotive industry relies heavily on cooling systems for vehicle engines, ensuring they operate at optimal temperatures and enhance overall performance. Each application highlights the diverse functions of cooling systems, reinforcing their importance in modern industrial operations.

As cooling technology continues to evolve, its future trends are becoming increasingly significant, particularly in addressing environmental concerns. The global heat management market is projected to grow from $11.48 billion in 2025 to $20.71 billion by 2034, with a compound annual growth rate (CAGR) of 6.73%. This growth is largely driven by advancements in HVAC technology, which integrate smart technologies allowing users to manage indoor environments remotely, ultimately leading to more energy-efficient systems.

Moreover, the cooling solutions for data centers are witnessing remarkable innovations. With the expansion of cloud computing services, the data center cooling market is expected to increase at a CAGR exceeding 13.5% from 2024 to 2032. These advancements focus on sustainability, as the industry recognizes the urgent need to optimize energy consumption in cooling operations.

**Tips:**

1. When selecting cooling systems, prioritize technologies that offer smart features for better energy management.

2. Consider the environmental impact of different refrigeration technologies to contribute to sustainability efforts.

3. Stay informed about the latest trends in cooling technologies, as they can significantly influence operational efficiency and costs.

| Cooling System Type | Mechanism | Applications | Future Trends | Environmental Impact |

|---|---|---|---|---|

| Vapor Compression | Refrigerant cycles through evaporator and condenser | Air conditioning, refrigerators | More efficient refrigerants, solar integration | Potential greenhouse gas emissions from refrigerants |

| Evaporative Cooling | Uses water evaporation to cool air | Industrial cooling, HVAC systems | Smart control systems, increased water efficiency | Reduces energy use, but requires water resources |

| Thermoelectric Cooling | Peltier effect generates cooling | Miniature refrigeration, electronics cooling | Advancements in materials, higher efficiency | Lower carbon footprint, materials sustainability is key |

| Magnetic Refrigeration | Magnetocaloric effect, cycles operate without fluids | Refrigerators, AC units | Development of practical applications, cost reduction | Minimal environmental impact with proper materials |